The packaging industry – like many others – is awash in mis-used and misunderstood terminology that can often lead to mistakes, cost-overruns and production delays. Aside from the typical challenges – converting imperial to metric, multilingual customers and employees, and ever-changing technology – packaging has an additional burden – confusing, contradictory and archaic terms that are not customer-centric. To make matters worse, there are a multitude of names for several products and materials, and because it’s “just packaging”, people are hesitant to ask for explanations or clarifications.

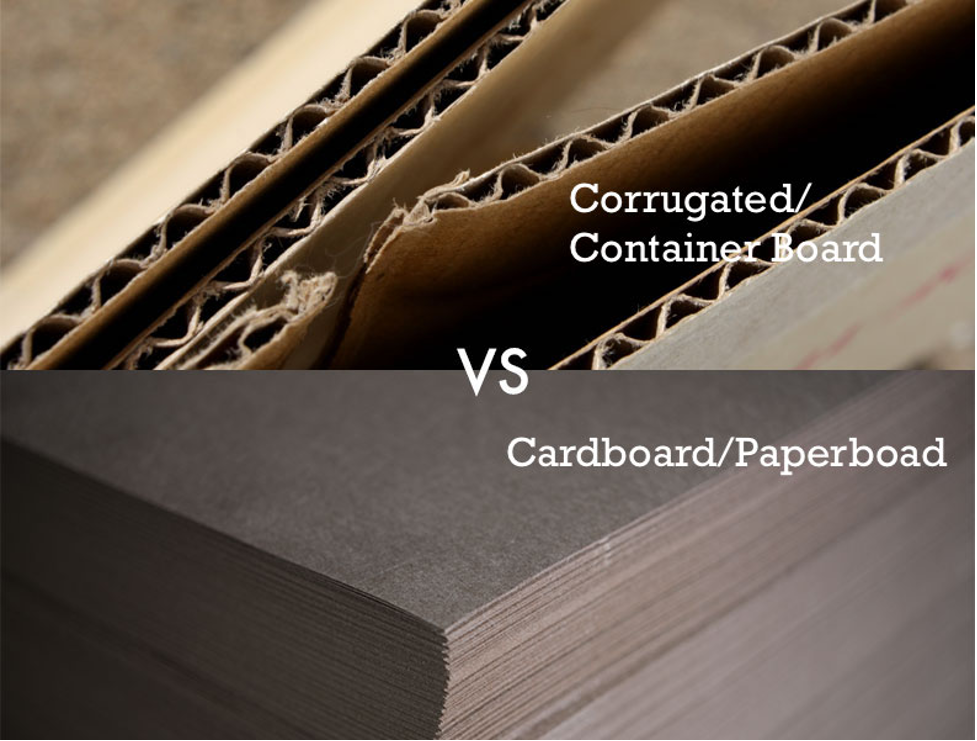

There is no better example to illustrate this point than by simply looking at the most prevalent packaging implement of the past 150 years – the shipping box. If you have ever called a shipping box “cardboard” you are in the company of millions of people that are using the wrong term. Shipping boxes are made from corrugated board – and it is the corrugation that makes them ideal for protecting shipments travelling around the globe. The corrugation is another term with several variations. Within the industry it is called the medium or flute – and the size and number of flutes are indicated by letters. B and C flute are the most common, and are often combined to make BC double-wall board. There are other flute sizes as well – A, E and F are also still used today. When you make different combinations of double and triple-wall board, the variety grows exponentially – and so does the confusion. It only gets more interesting when different paper weights are used to make different strengths, and of course there are colour options. With all of these options, it should be clear why it is important to understand the correct terminology.

So what is a cardboard box anyway? Cardboard is – like the name suggests – similar to card stock – more rigid than paper, but still bendable. Cardboard does not compare in structural strength to corrugated, but has advantages in printability and dexterity – they can be made much smaller than corrugated and can bend to make rounded products. Commonly found cardboard boxes are used for breakfast cereal, frozen foods, fragrances and pharmaceuticals.

So what is a cardboard box anyway? Cardboard is – like the name suggests – similar to card stock – more rigid than paper, but still bendable. Cardboard does not compare in structural strength to corrugated, but has advantages in printability and dexterity – they can be made much smaller than corrugated and can bend to make rounded products. Commonly found cardboard boxes are used for breakfast cereal, frozen foods, fragrances and pharmaceuticals.

The most common cardboard boxes are most usually called folding cartons, which as the name implies, are folded into shape by the customer prior to being filled. Set-up boxes – also referred to as rigid boxes – are also made of cardboard, but are pre-assembled at the manufacturing plant and are made of thicker cardboard. Folding cartons are disposable, while set-up boxes are used for longer-term use – i.e. it is expected the customer will keep the box.

Corrugated boxes are the world’s go-to for shipping goods – the corrugation provides the necessary stacking strength for building and stacking pallets for truck and container loads, as well as storage. The most common type of corrugated box is called a Regular Slotted Container (RSC) where the customer seals the bottom, loads the box, and then seal the top. The great advantage of RSC’s is that they can be manufactured without tooling. The machines that make RSC’s – we call them Flexo-Folder-Gluers (FFG) – can convert a plain, flat corrugated sheet into a finished box – even with printing – in a single pass, making them extremely efficient for quick turnaround and low converting cost.

Most other corrugated box options require more than one machine and often tooling, and are commonly referred to as custom die-cuts (CDC’s). Custom die-cuts are growing in popularity with the rise of on-line commerce, as they offer better durability and differentiation.

Most packaging requirements begin with the need to deliver a physical product from one place to another, without delay or damage. Boxes are responsible for a tremendous amount of this kind of packaging – just be sure to know the type of box you need.